From simulation to sea: How research is transforming cylinder lubrication

Through cutting-edge simulation of fluid dynamics, structural behaviour, and fluid–structure interactions, Dr. Flora Razavirad, R&D Engineer at HJ Lubricators, is redefining how lubrication works in two-stroke marine engines. The industry faces a pressing challenge: to reduce lubricating oil consumption, minimize piston and liner wear, and lower emissions without compromising performance. Combining academic rigor with practical engineering insight, Dr. Razavirad’s research translates complex science into tangible solutions that benefit shipowners and shipbuilders alike. With this expertise embedded in-house, HJ Lubricators stands out for its unmatched research depth and its commitment to cleaner, more efficient marine propulsion.

Simulation meets practice

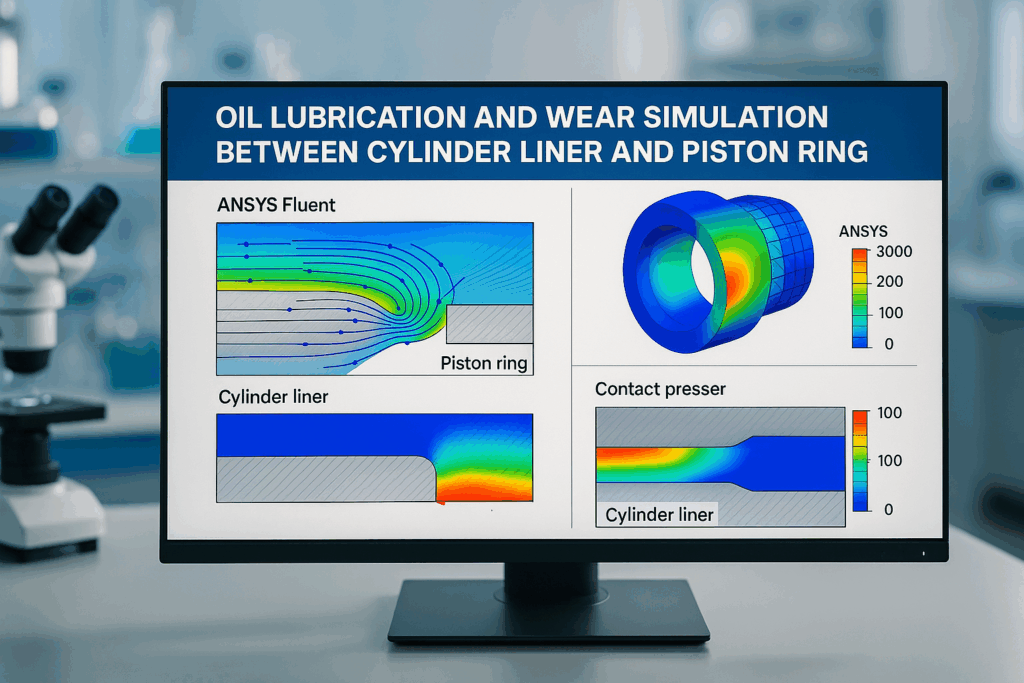

Flora’s research investigates how lubrication and airflow interact in large two-stroke marine engines — a field where advanced simulation meets real-world engineering. Her two recent publications represent significant contributions to this area: the first analyses scavenging airflows using varied turbulence models, providing insights into airflow dynamics and oil–air interactions in full-scale two-stroke engines; the second computationally studies wear behaviour in piston ring–cylinder liner assemblies, including lubrication-free conditions, to understand wear progression under different operational scenarios better.

“Although two-stroke engines are widely used in marine applications, detailed studies at full scale remain limited, particularly in modelling lubrication and wear,” she explains. “We implemented coupled CFD and structural models to analyse the interaction between in-cylinder pressure and contact mechanics in the piston ring–cylinder liner conjunction. The CFD simulations supplied pressure boundary conditions, and the ANSYS APDL model was used to predict dry wear based on these loads.”

Using advanced software such as OpenFOAM for fluid flow simulations and ANSYS APDL for mechanical and wear modelling, Flora combined fluid dynamics with structural mechanics to replicate realistic engine conditions. This hybrid approach is technically demanding, requiring custom coding, advanced numerical methods, and high-performance computing, but it yields critical insights into oil film thickness, pressure distribution, and wear evolution over thousands of simulated engine cycles.

“We started by simulating dry wear conditions as a baseline. In the next step, we will introduce lubrication to study where, when, and how much oil should be injected. Too much oil can reduce efficiency and increase environmental impact, while too little risks excessive wear. The goal is to identify the optimal balance.”

By analysing the liner’s material, hardness, surface roughness, and asperity characteristics together with the geometry and material of the piston ring and the tolerances in the ring–liner gap, Flora aims to determine the optimal oil film thickness required to minimise wear under varying operating conditions.”

Research Spotlight

Dr. Flora Razavirad

Position: R&D Engineer, Industrial Postdoc

Location: HJ Lubricators, Hadsund, Denmark

Funded by: Innovation Fund Denmark & HJ Lubricators

Dr. Flora Razavirad brings a unique blend of academic and industry expertise to HJ Lubricators. With a PhD in Engineering from the UK and research experience in France and Denmark, she specialises in Computational Fluid Dynamics (CFD), Finite Element Analysis (FEA), structural mechanics and simulation.

“I chose HJ Lubricators over a university postdoc because it offered the opportunity to make a direct impact. The collaboration here is dynamic and inspiring — it allows me to combine academic depth with real-world engineering challenges,” she says.

Originally from Iran, Flora moved to Denmark in 2023 to start her industrial postdoc. Her focus is on solving complex lubrication challenges through advanced simulation and applied research — directly supporting shipowners in achieving more efficient, lower-wear engine operation.

Direct impact for customers

The relevance for shipowners is clear. HJ Lubricators’ latest systems ensure even oil distribution, protect liners and piston rings, reduce maintenance requirements, and in many cases cut lubrication oil consumption by up to 50%.

“It’s not just about lubrication,” Flora explains. “It has a major influence on fuel efficiency, engine protection, and emissions. Our system keeps the engine cleaner, extends the life of liners and piston rings, and plays a crucial role when ships operate on different fuels. These are technical details customers might not see directly — but they make a real difference.”

Her research reinforces HJ Lubricators’ long-standing belief: technical excellence in lubrication is not a marginal issue — it’s central to cost control, sustainability, and regulatory compliance. Optimised lubrication reduces CO₂ emissions, lowers particulate output, and supports compliance with increasingly strict IMO standards.

Combining academia and industry

For Flora, the appeal of working in Hadsund lies in seeing research make a tangible difference.

“In academia, you can spend years developing models and publishing papers,” she says. “Here, you experience the entire process — from production to customer needs — and see how R&D directly contributes to real-world solutions. It’s a rewarding balance. And as a female engineer, I’ve found HJ Lubricators to be a very supportive and inclusive workplace.”

Her three-year industrial postdoc still has two years remaining, but Flora is already looking ahead.

“It’s an exciting journey,” she adds. “I see great potential to continue strengthening the bridge between simulation and practice.”