SIP+ revolutionises cylinder lubrication with easy retrofits, dual-fuel compatibility, and reduced emissions

Sometimes the biggest revolutions come from the smallest design changes. HJ Lubricators’ new SIP+ valve technology is one of them. By refining the company’s patented Swirl Injection Principle (SIP), engineers have eliminated the need for internal cylinder liner machining and top cover removal – a breakthrough that cuts installation time by more than a third.

Until now, installing SIP valves has required several days of immobilization or has been limited to installation during dry dock. Top cover removal and internal liner machining were unavoidable, making retrofits expensive and infrequent. With SIP+, preparation can be done while the vessel is at sea and the final installation conducted during a normal port stay.

“We have taken a proven technology and enhanced it,” says Mark Kristensen, Head of Sales at HJ Lubricators. “Previously, our engineers were traveling globally to machine liners. With SIP+, we can reach equal optimal lubrication at low feed rates without this step (to the benefit of everyone).”

The result is flexibility and more cost savings in retrofitting lubricator system(s). Shipowners and operators no longer need to consider the length of port stay. SIP+ can be installed during port calls, with minimal disruption.

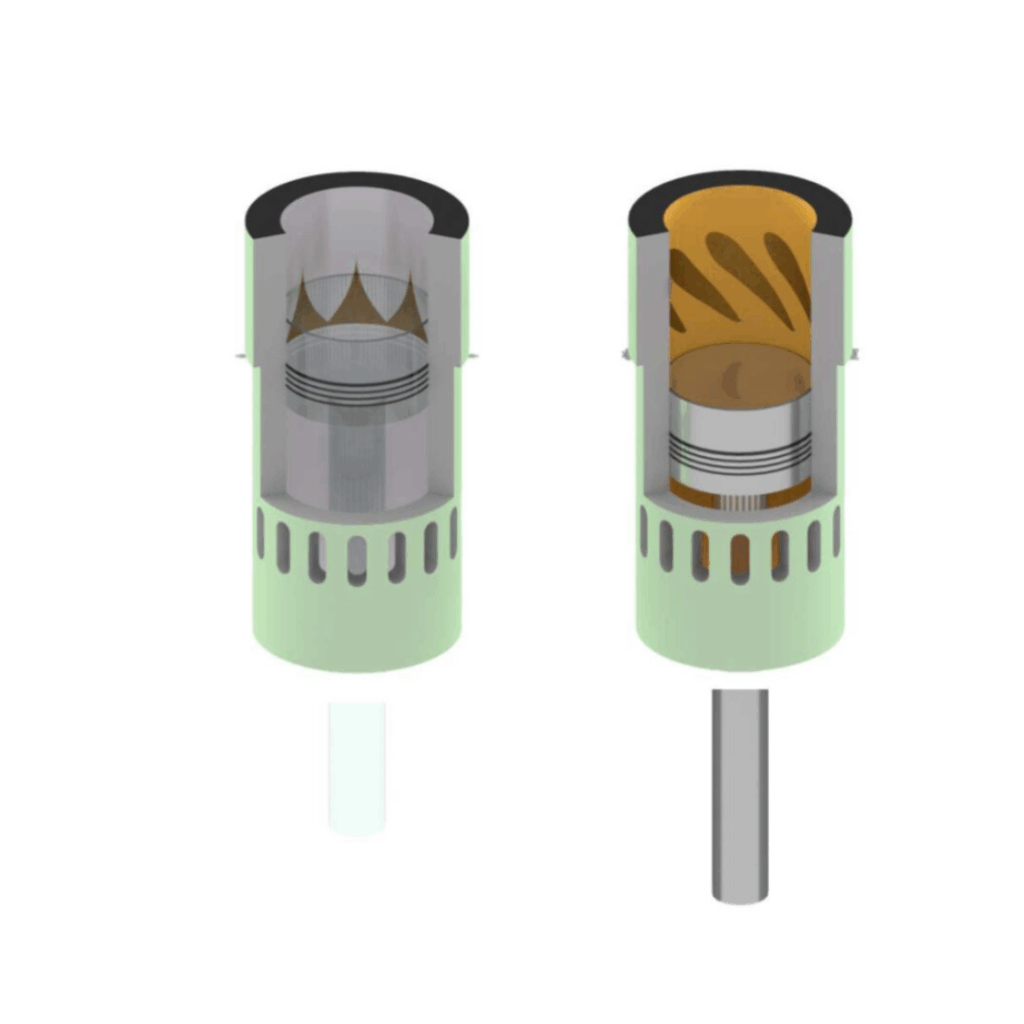

How SIP and SIP+ works

The Swirl Injection Principle is simple but effective. SIP is a high-pressure injection lubrication system that injects the cylinder oil as a spray above the piston. The oil is perfectly distributed on the upper part of the liner by injecting the oil into the scavenge air swirl. The air swirl lifts the oil and ensures a thin, uniform oil film on the upper liner. Due to the optimal distribution of the cylinder oil, the friction between the liners and rings is reduced, resulting in a lower feed rate and reduced wear rate.

SIP+ builds on decades of operational experience and academic collaboration. The new valve design maintains all the core advantages:

- Uniform oil film distribution

- Reduced liner wear and longer service life

- Lower lube oil consumption

Furthermore, SIP+ is:

- Compatibility with thin oil and dual-fuel operation

- Full compatibility with all existing lubrication systems

Economics and environment

Lower lube oil consumption translates directly into reduced operating costs. At the same time, less consumed oil means lower CO₂ and particle emissions – a tangible environmental benefit that helps owners stay ahead of tightening emission rules. “Shipowners invest in SIP+ to save money, but they also gain a cleaner operation,” Mark Kristensen says.

“Less oil consumed means fewer particles emitted, and that is becoming increasingly important across the industry.”

HJ Lubricators estimate a typical payback time of around three years. To give operators a more precise outlook, the company provides an online tool where expected savings is calculated

Market outlook

HJ Lubricators has a single focus: optimising cylinder lubrication for two-stroke marine engines. SIP+ represents the culmination of that focus, a small redesign with a big impact.

“This is not about inventing a completely new system,” concludes Mark Kristensen. “It is about refining proven technology, making it easier, faster, and cheaper to install. SIP+ is a small step in design – but a big step for engine operation.”

HJ Lubricators estimates that 10,000 ships worldwide could benefit from SIP+. With more than 3,500 lubrication systems already installed across the global fleet, the market is large.

Retrofits are the primary target, but the valve is also suited for newbuilds.