Cylinder lubrication systems explained: Performance, protection, and profitability

Efficient cylinder lubrication is vital for the reliable operation of marine engines, supporting operational efficiency, emission reduction, and the prevention of costly wear such as scuffing. HJ Lubricators recommends integrating robust cylinder lubrication systems as part of a vessel’s holistic approach to engine care, particularly where maximising uptime and meeting stringent IMO emission requirements are key success parameters for both technical managers and business stakeholders.

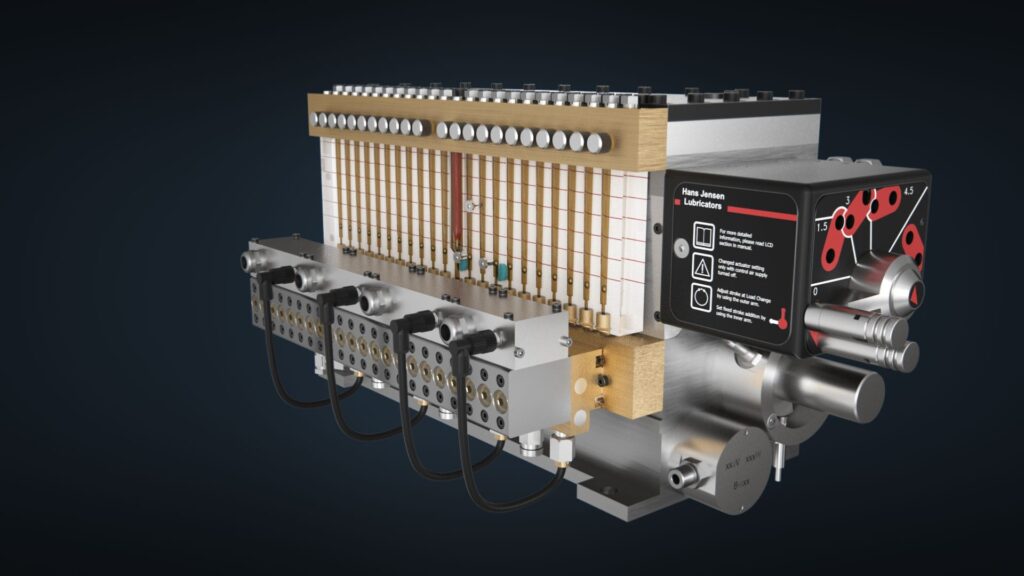

What is a cylinder lubrication system?

A cylinder lubrication system is designed to deliver precise quantities of lubrication oil directly to the cylinder liner and piston rings in large marine and stationary engines. Modern HJ Lubricators and other advanced solutions have revolutionised the process, ensuring targeted protection and reducing oil consumption for optimal engine operation.

Operational efficiency through optimal lubrication

Proper cylinder oil lubrication minimises mechanical friction between moving components. This helps maximise fuel efficiency and reduces the need for unplanned maintenance. Advanced systems, such as the marine engine cylinder lubrication systems developed by leading providers, monitor load, sulphur content in fuel, and engine speed to adapt oil delivery in real time. This improves engine running efficiency and extends service intervals, contributing directly to the vessel’s total cost of ownership (TCO).

Emission reduction and IMO compliance

The correct cylinder oil system is also pivotal in supporting environmental compliance by reducing the formation of corrosive compounds in the combustion chamber. By precisely dosing lubricant, these systems support the reduction of particulate emissions, helping shipowners comply with IMO MARPOL Annex VI and other international standards. Efficient cylinder oil lubrication systems reduce oil overconsumption, a key factor in emission control.

Scuffing prevention: extending engine life

Scuffing – damaging contact between the cylinder liner and piston rings can undermine operational reliability and result in expensive repairs. Leading types of cylinder lubrication systems are engineered to create a film barrier under all operating conditions, even with varying fuel sulphur levels. This technology intervention actively prevents liner wear and mitigates risk, protecting both engine integrity and operational profitability.

Types of cylinder lubrication systems

- Timed lubricators: Provide piston-position synchronised oil injection to maximise protective film at critical points.

- Load-dependent systems: Adjust oil dosage based on engine load, reducing oil waste and emissions.

- Electronically controlled systems: Respond to real-time sensor data for ultra-precise cylinder liner lubrication independent of operator intervention.

Why cylinder liner lubrication matters for your business

Investing in a high-performance cylinder oil lubrication system aligns with operational strategy, supporting:

- Maximal uptime and fewer unplanned maintenance stops

- Reduced oil consumption and operating costs

- Compliance with global environmental regulations

- Enhanced resale value and asset longevity

Conclusion

In the competitive maritime environment, a well-optimised cylinder lubrication system is not just a technical asset; it’s a strategic investment that enhances performance, improves compliance, and protects profitability. Contact HJ Lubricators for guidance on selecting the right system for your engine configuration and operational profile.

FAQs: Cylinder Lubrication Systems

What is the main function of a cylinder lubrication system?

The main function is to reduce friction and wear between the cylinder liner and piston rings, preventing scuffing and supporting efficient engine operation.

How does the right lubrication system reduce emissions?

By precisely dosing lubricant, it prevents oil overconsumption and minimises particulate emissions, helping vessels comply with international regulations like IMO MARPOL Annex VI.

Can advanced cylinder lubrication lower operational costs?

Yes. Advanced systems reduce oil wastage, decrease maintenance needs, and extend engine component life, all contributing to a reduced total cost of ownership.

Which system is best for my engine?

The most suitable system depends on factors such as engine size, operating profile, and regulatory requirements. HJ Lubricators offer a range of solutions adaptable to different marine applications.