White paper: Injection rate of cylinder lubrication oil in large two-stroke marine diesel engines using a common rail lubrication system

Insights from experimental validation using the Bosch ROI method

The paper, Injection rate of cylinder lubrication oil in large two-stroke marine diesel engines using a common rail lubrication system, was published in the International Journal of Engine Research by researchers: Bjørn Christian Dueholm, Jesper de Claville Christiansen, Benny Endelt, and Nikolaj Kristensen.

Precision in lubrication is essential to meet future environmental and operational targets

Cylinder lubrication plays a critical role in marine engine efficiency, emissions, and component longevity. This paper explores the capabilities of an electronically controlled, common rail-based lubrication system using the Swirl Injection Principle (SIP). Based on experimental research conducted by Aalborg University and HJ Lubricators, the findings support the system’s ability to dose lubrication oil with exceptional precision—even at very low volumes—using the Bosch Rate of Injection (ROI) method.

Introduction: The link between accurate oil dosing and emission reduction

Lubrication of cylinder liners in large two-stroke marine diesel engines is essential to ensure reliability and protect against wear. However, excessive lubrication leads to increased emissions of particulate matter, while insufficient lubrication compromises engine durability. Accurate oil dosing is therefore vital—not only for optimal engine performance but also to meet tightening environmental regulations.

Electronically controlled lubrication systems, such as the HJ SIP system, offer a unique opportunity to control the timing and quantity of oil injections with high precision. This whitepaper builds on experimental work evaluating such a system and its potential to enable more targeted, efficient lubrication strategies.

Experimental focus: Measuring injection dynamics with a high-viscosity oil

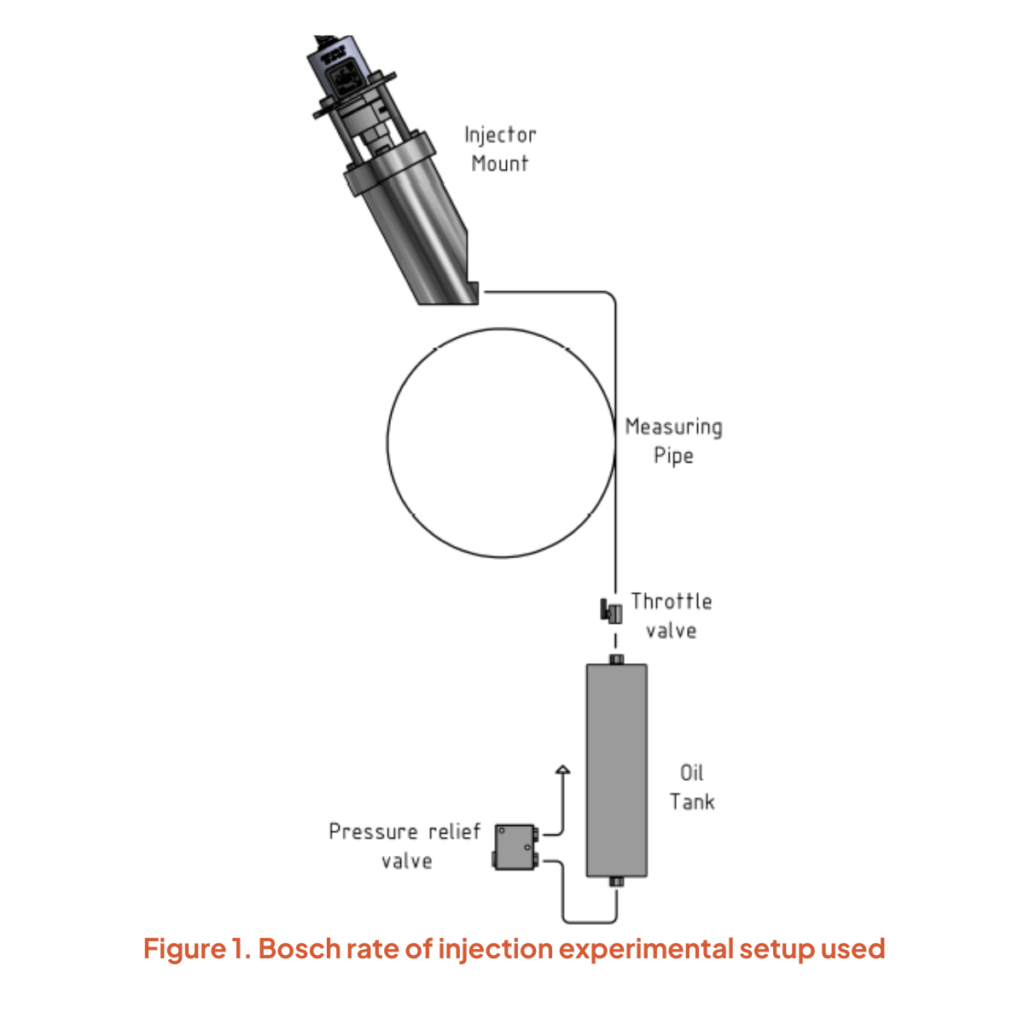

The study uses the Bosch ROI technique to experimentally characterise the injection rate of cylinder lubrication oil in a common rail-based system. The experiment simulates real engine conditions and evaluates the system’s ability to inject oil at volumes down to 2.5 mg with high repeatability.

The injector setup consists of:

- A solenoid-controlled single-hole injector

- An 8-metre measuring pipe with a piezoelectric pressure sensor

- A common rail pressurised to 70 bar

- Back pressure set at 8 bar

- Injection fluid with viscosity matching heated cylinder oil

HydraWay HVXA15 was used as the working fluid to represent the properties of actual marine lubrication oil at operational temperatures. The system was tested across varying current ramp times (6.6 to 7.3 ms), and the results were validated against real mass measurements.

Results and observations

Key findings from the experimental study include:

- Rapid mass flow rise: The oil injection reaches peak flow within ~1 millisecond before cavitation limits the flow rate.

- Atomisation supports the SIP principle: Cavitation contributes to oil atomisation, which is crucial for effective swirl-assisted distribution on the liner.

- Linear injection behaviour: There is a near-linear correlation between ramp time and injected mass, making system calibration straightforward.

- High measurement fidelity: The Bosch ROI method delivered results within a 5% error margin compared to physical measurements, validating its use for highly viscous fluids.

These findings underscore the system’s capability to perform precise, repeatable injections, which is critical for advanced control strategies and multi-pulse lubrication.

A step forward in intelligent lubrication

The results validate not only the performance of HJ Lubricators’ common rail SIP system but also its potential to drive innovation in engine lubrication:

- Enables load-dependent oil strategies

- Reduces overall lubrication oil consumption

- Lowers particulate emissions

- Improves engine wear protection through precise timing and volume control

With the ability to dose as low as 2.5 mg per injection and execute multiple injections per piston stroke, the system represents a new level of control and adaptability in marine lubrication.

Key takeaways:

- Fast injection dynamics enable targeted delivery

- Verified dosing down to 2.5 mg per injection

- System supports multi-injection strategies

- ROI method is valid for marine lubrication oil measurements

HJ Lubricators is ready to support shipowners and engine builders with cutting-edge lubrication systems that meet the challenges of tomorrow..

Proven technology, ready for next-generation engine performance

The combination of electronically controlled valves, swirl injection, and common rail technology makes HJ Lubricators’ system a robust solution for modern engine demands. The verified accuracy of the injection system opens the door to further enhancements in engine efficiency, emissions reduction, and maintenance optimisation.

Unlock the Full Potential of Your Engine

Are you looking to optimise cylinder oil consumption, reduce particulate emissions, and extend engine lifetime?