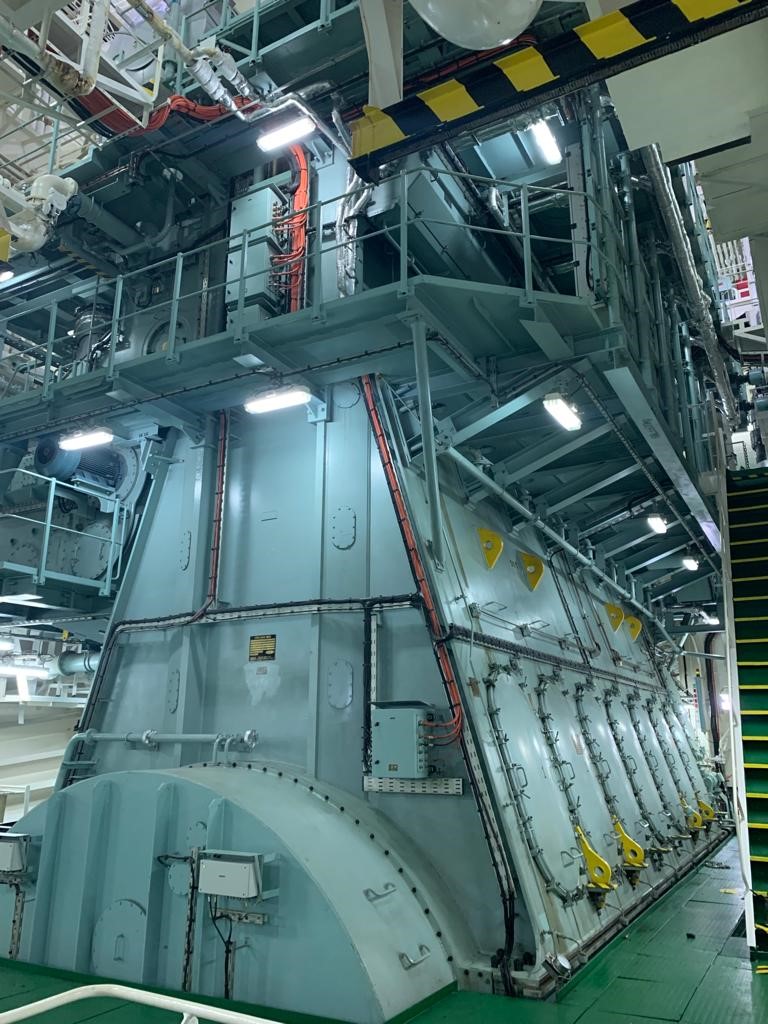

Keep your two-stroke marine engine running efficiently

The maritime industry relies heavily on two-stroke marine engines to power the vessels. These engines are highly efficient. However, they require proper lubrication to function at their best. Lubrication is an essential component of any engine, and it is especially critical for two-stroke marine engines. The right lubricant and lubrication system help to reduce friction, prevent wear, and extend the lifespan of the two-stroke engine.

Learn more about HJ Lubricators’ lubrication system and how it keeps your two-stroke marine engine running smoothly and efficiently below.

Why is proper maintenance important for two-stroke marine engines

Proper maintenance and regular servicing identify any potential issues in your two-stroke marine engine before they become major problems. Neglecting maintenance can lead to decreased performance, increased fuel consumption, and a shortened time between overhauls.

Today, ship owners face several challenges. One is the frequency of crew change, which might weaken knowledge sharing between members and accumulation in the long run. Also crew responsibilities tend to become broader with less room for specialisation in lubrication and other areas. Finally, technology becomes more complex, and the introduction of new fuels is one factor that challenges efficient cylinder lubrication.

HJL offers a full framework of services, helping you to get the most out of your lubrication system. Our approach takes a broader view of cylinder maintenance to offer you the optimal solution. Take our Cylinder Condition Optimisation Program. This is the most comprehensive service program in the world, centered around maintaining cylinder efficiency. We use our knowledge that has been collected over decades and find the best way forward in close collaboration with you.

In addition to regular maintenance, using a reliable lubrication system will further extend the lifespan of your two-stroke marine engine. With the right system, your two-stroke marine engine can operate at its best and reduce friction, minimise wear, neutralise acids, keep piston rings free of deposits, and finally provide a gas-tight seal between cylinder liner and piston rings.

Explore our cylinder condition optimisation program ->

The advantages of HJ Lubricators’ lubrication system for two-stroke marine engines

HJ Lubricators is the leading provider of lubrication systems for two-stroke marine engines. Our systems are designed to provide reliable and efficient lubrication.

Reduced operational cost

Achieve significant reduction in cylinder lubrication oil consumption – up to 50% – lower CO2 and particulate matter emissions, and finally, extend cylinder liner lifespan by minimising wear on liners and piston rings. Combined, all of these factors will lead to reduced operational costs.

Prepare for a greener future

HJL technology supports the future use of greener fuels and switching between fuel types. Our solutions provide the flexibility needed for injecting lube oil during every piston stroke, varying the angle and timing according to fuel profile.

Increased transparency

HJ Smartlink™ is a brand-new digital lubrication platform for remote monitoring of several parameters. Keep an eye on feed rate, oil consumption, and get alarms or notifications are just a few of the options available for you.

Understanding lubrication in large two-stroke marine diesel engines

Two-stroke marine diesel engines are the workhorses of global trade, powering everything from container ships to bulk carriers. These large 2-stroke engines operate under extreme thermal and mechanical stress, making efficient cylinder lubrication vital for long-term reliability and compliance.

Modern lubrication systems – utilising HJ SIP (Swirl Injection Principle) – distribute oil precisely inside the cylinder, targeting high-load zones and neutralising acid formation caused by cold corrosion. This is essential for ensuring stable engine performance and for protecting cylinder liners and piston rings from scuffing and deposits.

In large ship main engines, even small improvements in lubrication efficiency can lead to substantial savings on operational costs and emissions. That’s why HJ Lubricators remains a trusted partner for shipowners and operators worldwide.

Future-proofing your 2-stroke marine engine with HJ SIP

HJ SIP is designed specifically for two-stroke marine diesel engines and ensures uniform oil distribution across the entire liner surface. This reduces oil waste, enhances piston ring performance, and stabilises engine operation even under varying fuel types or operating profiles.

Whether for newbuilds or retrofitting existing ship engines, our lubrication systems support the industry’s transition to greener shipping, without compromising on engine integrity or uptime.

Frequently Asked Questions

What is a two-stroke marine diesel engine?

A two-stroke marine diesel engine is a type of internal combustion engine used in ships, known for its high power output and fuel efficiency. It completes a power cycle with two strokes of the piston and is typically used as a ship’s main engine.

How does a lubrication system work in a 2-stroke marine engine?

Cylinder lubrication systems inject small quantities of oil directly onto the liner surface during engine operation. Advanced systems like HJ SIP ensure precise timing, location, and quantity, reducing wear and improving combustion efficiency.

What are common lubrication challenges in large ship engines?

Key challenges include scuffing, cold corrosion, excessive oil consumption, and insufficient acid neutralisation. These issues can reduce engine efficiency and increase maintenance frequency if not properly addressed.

How can I reduce oil consumption in a two-stroke marine engine?

By upgrading to a modern lubrication system such as HJ SIP and implementing regular monitoring through platforms like HJ Smartlink™, operators can reduce oil consumption by up to 55% and extend engine component life.

Why is lubrication critical to marine engine performance?

Proper lubrication reduces friction and heat, prevents wear and deposits, and maintains sealing between piston rings and liners — all of which are essential to reliable, fuel-efficient operation.